Background

U. S. Forensic was retained by our client to perform a key analysis. It was reported that a 2003 Chevrolet Trailblazer was reported stolen. There were 2 keys and a single keyless entry transmitter for the vehicle. Both of the keys and the keyless entry transmitter for the vehicle had been accounted for; but at the time of the evaluation, the vehicle had not yet been recovered. The 2 keys and the single keyless entry transmitter for the Chevrolet were examined, tested and photographed by Jeffrey P. Stark, P.E. and Forensic Locksmith at the U.S. Forensic facility in Metairie, Louisiana.

The 2003 Chevrolet Trailblazer was equipped with the General Motor’s Passlock vehicle theft deterrent system. The design of the Passlock system is to prevent vehicle theft by disabling the engine unless the ignition lock cylinder rotates properly by engaging the correct ignition key. The theft deterrent system has been incorporated into the body control module (BCM). The theft deterrent is provided in order to prevent vehicle operation if the correct key is not used in order to start the vehicle. The ignition key turns the lock cylinder, and the cylinder rotation produces an analog voltage code in the Passlock sensor. This voltage code is received by the BCM, and the BCM compares the voltage code to the previously learned voltage code. If the codes match, a class 2 message is sent from the BCM to the powertrain control module (PCM) to enable the fuel injectors that will allow the engine to start.

Typically, 2 keys and 2 keyless entry transmitters were issued with the vehicle when the vehicle left the factory, and the vehicle used 1 key for all the locks on the vehicle. The key for this year model vehicle is a 10-cut key with 4 depths for the cuts. The ignition lock cylinder for this vehicle utilizes cuts 1 through 9. The door lock cylinders utilize cuts 3 through 9, the lift gate lock cylinder utilizes cuts 4 through 10, and the optional glove box lock cylinder utilizes cuts 7 through 10.

Evaluation

Physical/Microscopic Evaluation

The keys were examined under 40X and 100X microscopes. Neither of the keys presented were an original equipment manufacturer (OEM) issued key for the vehicle. The mechanical cuts on both of the keys matched and the observations made to both of the keys were nearly identical. Further examination revealed that both of the keys were aftermarket keys manufactured by HY-KO for a non-transponder vehicle and were the correct type used for this year model vehicle.

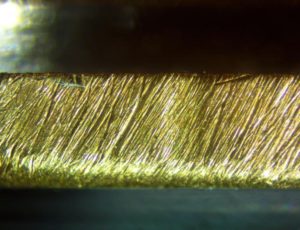

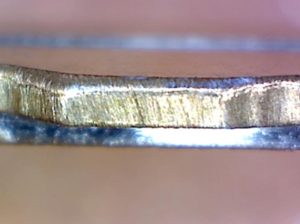

Examination of the blades of the keys revealed that both of the key blades had the proper nickel-plate over brass core finish. There was no tarnish, dirt or wear observed on the blades from normal use. There were tool marks on the key blades that would indicate the keys were recently used in a duplicating process. The ramps, curves, and slopes of the key cuts on both keys were worn down from extensive buffing of the key cuts and not long-term use. There were diagonal striations across the cuts of the key consistent with the buffing of the key cuts using a metal radial wire wheel. There were no markings observed on top of the diagonal striations across the key cuts consistent with the key having been inserted into or used to operate a lock cylinder.

Decoding of Keys

The cuts of the keys were measured using a plastic dial caliper and the bittings were decoded from bow to tip as 3431124221. Using the VIN from the subject vehicle, the original factory key code was obtained from the manufacturer. The key code that was issued to the subject vehicle at the factory was S199C for both the ignition and compartment keys. This key code was cross-referenced to key cuts using a key code decoder program. The key cuts from bow to tip based on the key code provided were noted as 1232424312, which did not match the cuts of the keys issued for examination.

Based on the evidence observed, it is our opinion that both key number 1 and key number 2 were newly cut keys and had not been used to operate a lock cylinder after being buffed extensively with a metal radial wire wheel.

Findings

Examination and analysis of the keys presented for the vehicle revealed that both of the keys were aftermarket keys. There was evidence that indicated the keys were used in a duplicating process and had been recently buffed extensively with a metal radial wire wheel. There was no evidence that indicated either key was used to operate a lock cylinder after being buffed extensively with a metal radial wire wheel.

The keys did not contain the correct cuts to operate any of the lock cylinders that the vehicle was originally equipped with from the factory. If the ignition lock cylinder for the subject vehicle had been replaced, one would expect the ignition lock cylinder to have been rekeyed to match the original key cuts for the vehicle or the vehicle would have 2 keys with different mechanical key cuts, 1 new key to operate the new ignition lock cylinder and another key with the original key cuts from the factory to operate the door lock cylinders, lift gate lock cylinder and the optional glove box lock cylinder. It would be rare and unusual for all of the lock cylinders on the vehicle to have been rekeyed for a key that was different from what was originally issued from the factory.

Examination of the keyless entry transmitter presented for the vehicle revealed that the transmitter was an OEM issued remote keyless entry fob transmitter of the proper type used for this model year vehicle remote locking system. The plastic housing of the transmitter displayed evidence indicative of long-term wear from normal use. The long-term wear of the transmitter did not match the minimal amount of wear observed on the keys presented for examination.

There are possible methods to defeat or bypass the theft deterrent system of the Chevrolet. One method involves either drilling the center of the ignition lock cylinder or between the cylinder housing and the side bar location and then force rotating the lock cylinder. Another method would be to apply pressure on the sidebar with a tool while attempting to pick the lock cylinder. If either of these methods were used, there would be evidence of tool marks on the wafers, sidebar and the keyway of the faceplate. Examination of the vehicle, once recovered, would be required to determine if there was any evidence of an attempt to bypass the ignition lock cylinder.

In order for the vehicle to have been started and driven away, a proper key was used that contained the correct mechanical cuts which allowed the rotation of the ignition lock cylinder and also allowed the Passlock sensor to produce and send an analog voltage code to the Body Control Module (BCM) that matched the previously learned voltage code. The BCM then sent a class 2 message to the Powertrain Control Module (PCM) that enabled the fuel injectors and allowed the engine to start.

Photographs

- View of Key No. 1

- Microscopic view of the cuts of the key for key No. 1. Note the diagonal striations on the surface of the key cuts with no markings on top of the striations from recent use in a lock cylinder and the rounded edges of the cuts from extensive buffing.

- View of the tip of the blade of key No. 2. Note the rounded edge of the key cuts and the markings on the blade from buffing.

- Microscopic view of the cuts of the key for key No. 2. Note the diagonal striations on the surface of the key cuts and the rounded edges of the cuts from extensive buffing.

- View of the testing of the key transponder.

- View of the testing of the keyless entry transmitter.