Published in the November/December 2022 Issue of Claims Magazine, Claims Subrogation Showcase

Why Engage a Forensic Engineer in your Subrogation Case?

Forensic Engineers are experienced at providing defensible opinions as to the cause of the failure through documentation of evidence and testing procedures. However, the benefits of using a forensic engineer, according to USF Mechanical Engineer Eugene Lopez-Ona, P.E. (Lafayette), goes even further: “This must be done in a controlled manner so that spoliation claims are avoided. Forensic firms have the facilities and know-how to test and document the condition of failed components, and initial testing can be done quickly and with minimal expense to determine if there may be a basis for subrogation.”

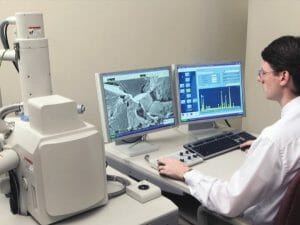

Another USF Mechanical Engineer, Dan Cross, P.E. (Orlando) added “We (forensic engineers) are trained in the proper scientific approach to assessing failures and losses. This includes the proper handling of evidence as laid out by NFPA and ASTM standards and having the proper equipment to do the analysis necessary for a variety of circumstances.” In fact, U.S. Forensic engineers have access to specialized equipment and a 155,000 square foot accredited laboratory to conduct testing and store evidence.

Specialized U.S. Forensic equipment (not widely available) includes:

- Optical Fractography

- XRD (X-ray powder diffraction)

- Scanning Electron Microscopes

- FTIR (Fourier Transform Infrared Spectroscopy) & EDS (Energy-Dispersive X-ray Spectroscopy)

- Laser Scanning Modelling

- CAT Scans

What Can Claims Professionals do to Contribute to a Successful Subrogation Evaluation?

Documentation – anything and everything. Often our engineers will receive a failed product or component to examine. In many cases, their findings from the failure analysis can stand alone. However, key documentation obtained by the claims professional can make or break a case. For example, U.S. Forensic had a case which demonstrated why documenting the in-situ condition during the initial site visit can prove valuable.

U.S. Forensic was asked to evaluate a water heater to determine the cause of failure. Our engineer requested that the condition of the water heater be documented including its installation prior to its removal. The joint exam with the manufacturer was scheduled to take place at our engineering laboratory months later. At the joint inspection, our engineer used a flow meter to confirm the leak and its location – the seam weld of the tank. Further analysis determined that the weld did not fuse both ends of the tank’s steel which indicated a defect in the manufacturing process. Both experts agreed. This is a definite case for subrogation, right? Not so fast.

Two months later the manufacturer confirmed that there was a defect; however, they were going to offer 50% of the claims value because improper installation couldn’t be ruled out. The documented condition of the water heater prior to its removal proved extremely valuable. With this evidence, the manufacturer changed their position and ended up paying 95% of the claims value.

Procedures – It is essential to have good evidence procurement in these cases. Mr. Cross, P.E. states, “We need a good chain of custody for evidence and need to document the as-installed condition, electrical connections, water pressures, etc.” Without the documentation of the environmental conditions, it is more difficult to successfully subrogate against a manufacturer. Mr. Cross recommends, when feasible, sending a forensic engineer to the scene to document, collect, and secure evidence.

Please visit Claims Magazine’s November/December 2022 Issue to access the article. For more information on how we may be able to assist with your case, visit our Product Liability page or Contact Us to speak with one of our experts.