Jeff Stark, P.E.

A winter freeze caused a fire protection sprinkler system failure at an elementary school in northern Texas causing the fire protection sprinkler system to operate and distribute water into the attic area of the school. U.S. Forensic was asked to determine the cause of the fire protection sprinkler system failure. The mechanical engineer assigned to the case was Jeffrey P. Stark, P.E.

Case Background

The elementary school houses a wet and a dry pipe sprinkler system for fire protection. The wet pipe sprinkler system is intended for systems that will be protected by adequate heating or insulation and will not be exposed to below 40°F temperatures. The dry systems are intended where the temperature may reach 40°F and below. In a dry-pipe firewater system, the sprinkler piping is charged with compressed air rather than water. The compressed air holds the dry valve closed and prevents water from entering the system. When a sprinkler head is activated by the heat of a fire, the air exits the system and reduces the pressure on the outlet side of the dry valve. This allows the dry valve to open and water to flow to the activated sprinkler head.

An interview with the staff at the school revealed that they performed the routine inspections and tasks on the fire sprinkler system as part of the school’s monthly fire drill. One of the staff members was trained on performing these inspections and tasks by the local fire department. They performed the draining of the dry pipe sprinkler system at least twice at every location depending on the amount of water that is drained. When they performed the draining of the west end of the dry pipe sprinkler system, very little water came out as compared to the east end dry pipe sprinkler system.

Examination of the sprinkler system revealed that a tee pipe fitting for the dry pipe system in the west side of the attic had fractured.

Analyses & Findings – Sprinkler System Failure

Sprinkler Installation

View of the levelness on the dry pipe sprinkler system piping. The red arrow indicates the tee pipe fitting that failed.

According to the National Fire Protection Association (NFPA), the branch piping in a dry pipe sprinkler system shall be pitched at least ½ inch per 10 feet for drainage. The piping (north of the support) on the south run of the dry pipe sprinkler system was sloped towards the failed tee pipe fitting instead of being sloped towards the drain location. This proved that all of the water would not drain from the dry pipe sprinkler system. The tee pipe fitting that failed was midway between supports on the run of the tee. It supported the inlet of the branch piping which came from a higher elevation. There were no supports near the end of the branch piping. This induced an additional load on the tee pipe fitting and allowed the tee pipe fitting to sag between the run piping supports. This induced sag between the piping supports allowed water to collect in the tee pipe fitting that could not be drained.

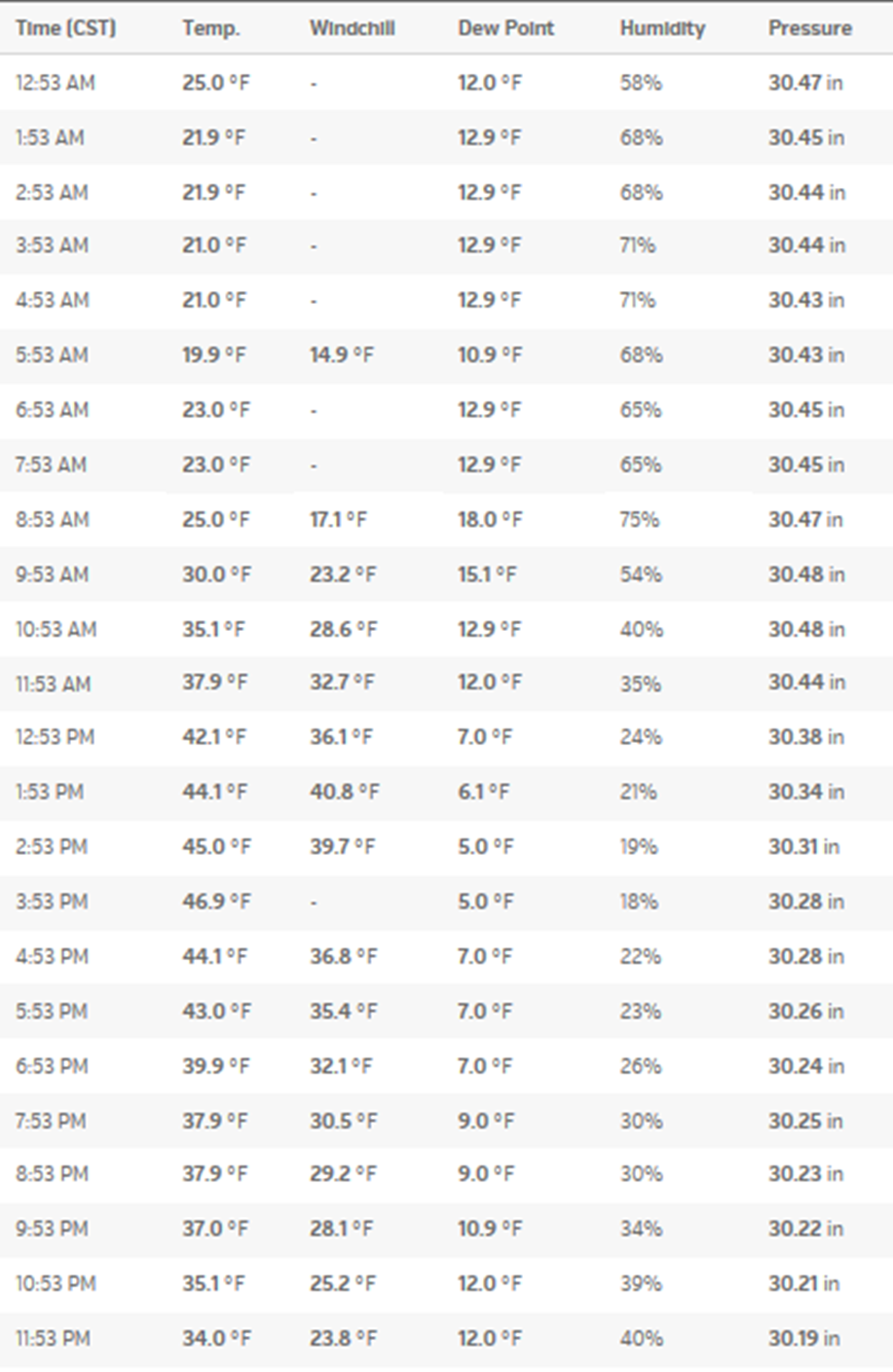

Weather Data

The temperature remained in the low 20’s until 8:00 am and remained below freezing until 10:00 am. The rupture of the tee pipe fitting of the dry pipe sprinkler system was caused by water that remained in the pipe fitting even after being drained, freezing and turning to ice. The expansion of water into ice caused the rupture of the tee pipe fitting.

Conclusions

Based on information obtained and considered to date, U.S. Forensic has determined that the piping for the dry pipe sprinkler system where the failure occurred was not built to code as per the National Fire Protection Association 13: Standard for the Installation of Sprinkler Systems, which states that the branch piping in a dry pipe system shall be pitched at least ½ inch per 10 feet.

Photographs

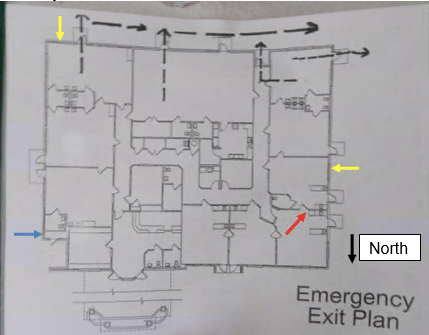

- View of the layout of the school. The blue arrow indicates the valve room location, the red arrow indicates the location of the pipe tee failure, and the yellow arrows indicate the drain locations for the dry fire water system.

- View of the room below the location where the tee failure occurred. The red arrow indicates the tee failure location.

- View of the valve room for the fire sprinkler system. The red arrow indicates the dry valve for the dry pipe sprinkler system.

- View of the tee fitting that was replaced after the failure event. The yellow arrow indicates the nearest support between the tee fitting and the drain.

- View of the piping on the south run of the tee pipe fitting.

- View of the tee fitting that was replaced after the failure event. The yellow arrow indicates the support on the north side of the tee fitting.

- View of the branch piping going to the tee fitting.

- View of the branch piping going to the tee fitting. The yellow arrow indicates the support on the branch piping.

- View of the levelness on the dry pipe sprinkler system piping between the tee fitting and the drain. Note at this location the piping is sloped 0.2° down toward the tee fitting to the right.

- View of the levelness on the dry pipe sprinkler system piping on the other side of the pipe hanger which is sloped 0.1° down toward the drain.

- View of the levelness on the dry pipe sprinkler system piping. The red arrow indicates the tee pipe fitting that failed.

- Close up view of the level reading on the dry pipe sprinkler system piping showing that it is sloped 0.3° down toward the tee pipe fitting to the right of the picture and not the drain.

- View of the drain piping at the exterior of the southeast corner of the building. Note the rust stain on the wall.

- View of the tee fitting that failed.

- The weather near the loss location in Texas on the day of the loss event.

U.S. Forensic Services

To learn more about investigations similar to sprinkler system failures, visit our product liability page. For a full list of services, please visit our forensic services page.