Engineering Laboratory Services

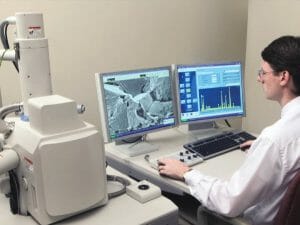

U.S. Forensic is a member of the ATS Family of Companies. With this partnership, our clients have access to most advanced technology housed in a 150,000 square foot engineering laboratory. Failure analysis, metallurgy, materials testing, chemical analysis and a vast evidence storage facility are available to customers. We provide our clients with information on the cause and origin of a component, appliance, equipment or material failure and identify subrogation potential. Large items such as vehicles, airplanes, or tractor tires can be sent to our laboratory for expert evaluation. Small items such as components, fasteners, sprinkler heads, or various materials can also be shipped to our laboratory for a comprehensive evaluation.

The engineering laboratory has over 100 technology sector vendor approvals and has a long list of accreditations. A few include:

- ISO 9001

- Accredited to 17025*

- 10CFR50 Appendix B

- ANSI/NCSL Z540-1

- ASNT-TC-1A

- MIL Standard 410

Failure Analysis & Metallurgical Services

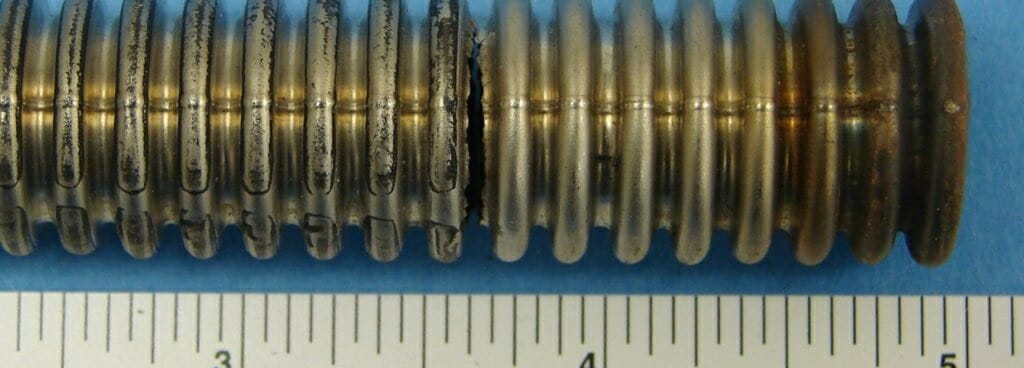

Whether you are investigating a single component or dealing with a system failure, you can rely on our Failure Analysis team’s expertise and testing techniques to meet your full failure analysis needs. From fractures to formability problems, corrosion to wear, our analysts will find the root cause of the failure and assist in plans for prevention.

Our metallurgists and professional engineers routinely conduct failure analyses on a wide variety of materials, including steels, stainless steels, titanium, super alloys, copper alloys, aluminum, plastics, ceramics and glass. We understand that you don’t just need testing, you need interpretation. Our engineers and metallurgists consult with you to determine the full scope of every project-factors such as the material of manufacture, the size and shape of the component, and the specification influence the testing decisions.

Testing Techniques

- Scanning Electron Microscopy

- Energy Dispersive Spectroscopy

- Optical Fractography

- Hardness Testing

- Mechanical Testing

- Chemical Analysis

- XRD (X-ray powder diffraction)

Materials Testing in Engineering Laboratory

- Weld Testing & Qualifications

- Special Testing (customized load tests, pressure tests, wear/fatigue tests)

- Load Testing

- Pressure Testing

- Hardness Testing

- Strain Gage Testing and Strain Measurements

Evidence Storage and Joint Inspections

Our accredited testing lab offers the space, equipment and the manpower necessary for your next litigation joint inspection. Whether you are a manufacturer in need of an analysis of a reported failure (what, how or why it happened?) or an attorney litigating a product liability case, our forensics team of experts is ready to help.

From experience, we understand the importance of rendering an opinion (and reasons for them) that will withstand judicial scrutiny and are effectively communicated to the trier of fact. Our operation is the benchmark for any joint accident or incident investigation as we are the biggest, most prepared lab in the southeast. We also have a large secured facility for your evidence storage needs.

Featured Experts for this Forensic Service

| Name | Title |

|---|---|

| Jacob Cicero, P.E., CPD, GPD | Professional Engineer |

| Michael DeHarde, P.E. | Partner / Principal Engineer |

| Jeremy Hoffpauir, P.E., ACTAR | Professional Engineer / Accident Reconstructionist |

| Erick H. Schlender, P.E., CFEI, CVFI | Professional Engineer/Fire Investigator |

| Jeffrey Stark, P.E., CFL | Professional Engineer / Certified Forensic Locksmith |