Metallurgical Testing

Metallurgical Testing

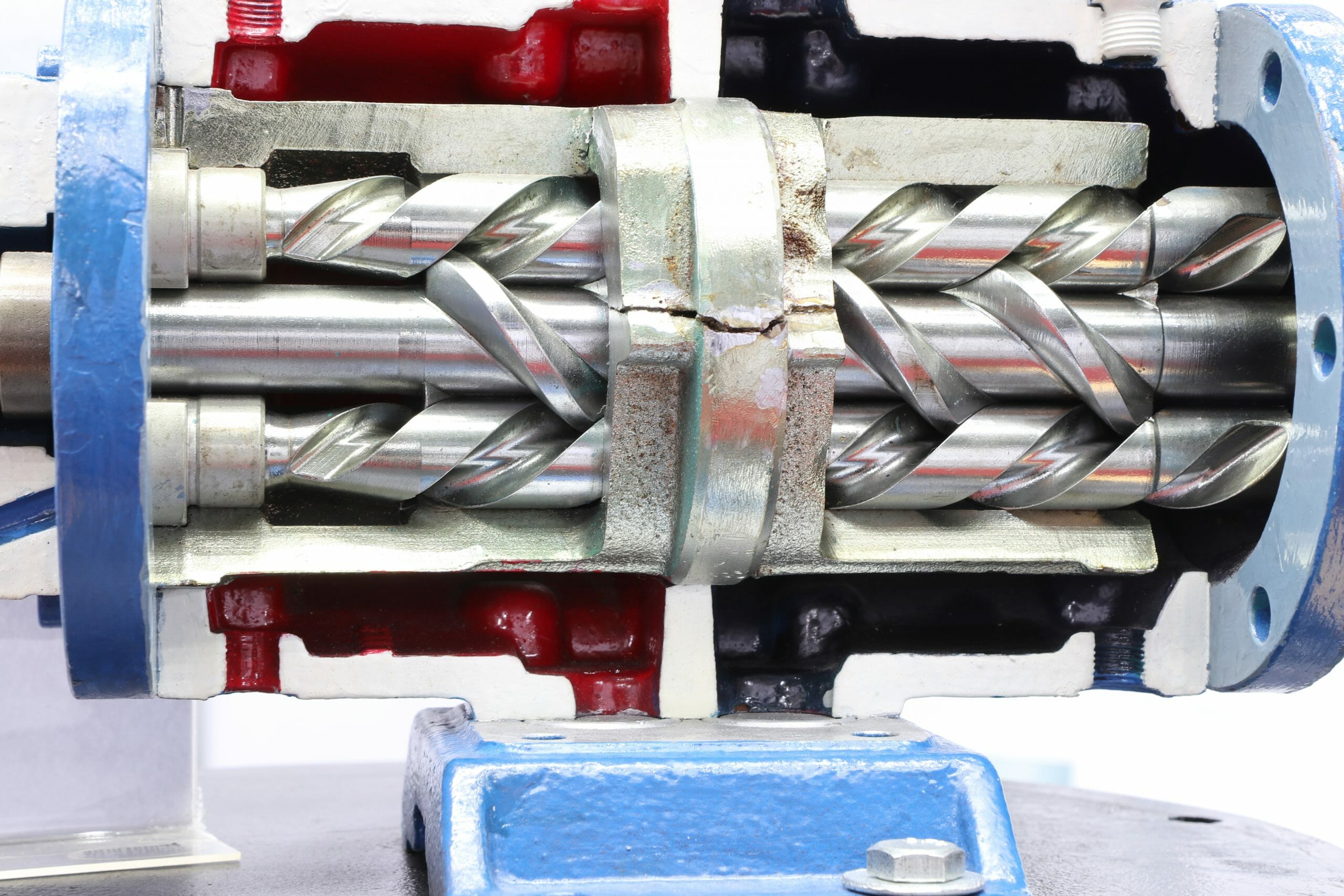

U.S. Forensic performs metallurgical testing on failed equipment, structural components, oilfield, natural gas, and plant equipment, piping, storage tanks, hydraulic systems, valves, fasteners, and metal structures. Whether you are investigating a single component or dealing with a system failure, you can rely on our Failure Analysis team’s expertise and testing techniques to meet your full failure analysis needs. From fractures to formability problems, corrosion to wear, our analysts will find the root cause of the failure.

Metallurgical Testing Techniques

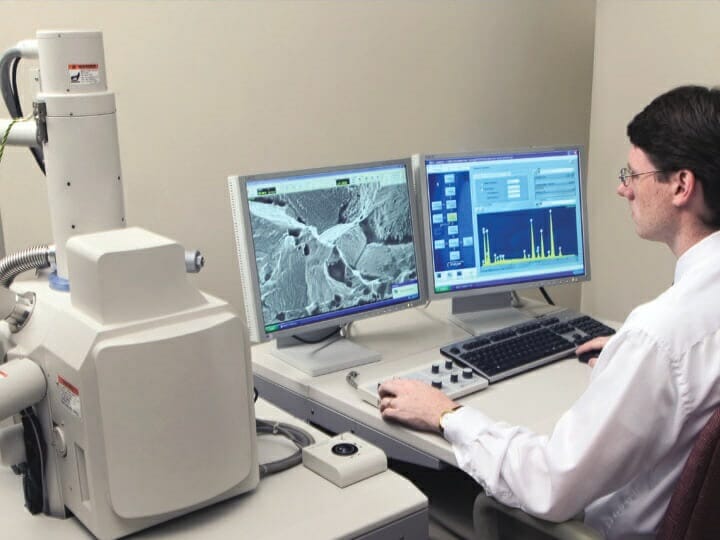

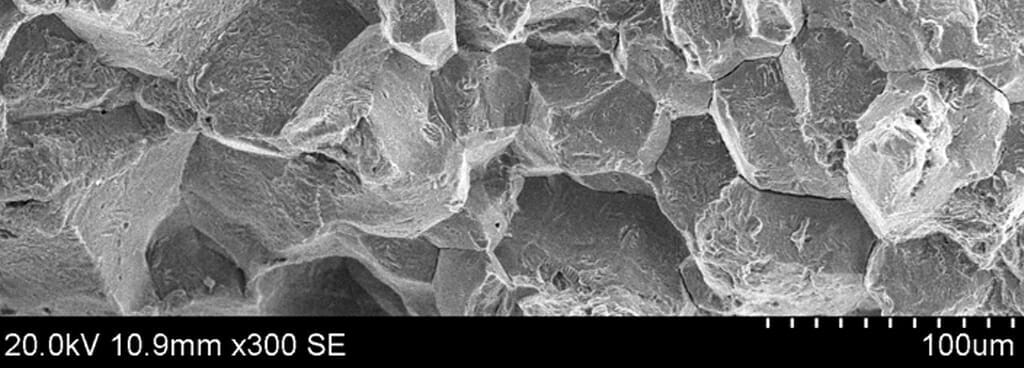

- Scanning Electron Microscopy

- Energy Dispersive Spectroscopy

- Optical Fractography

- Hardness Testing

- Mechanical Testing

- Chemical Analysis

- XRD (X-ray powder diffraction)

Metallurgical Analysis

Our experts conduct a metallurgical analysis to determine if a mechanical, structural, or component failure is due to:

- Defective material

- Improper design

- Manufacturer defect

- Corrosion

- Improper welding

- Poor Installation

- Chemical contamination

- Improper maintenance

Failure Analysis

Our metallurgists and professional engineers routinely conduct failure analyses on a wide variety of materials, including steels, stainless steels, titanium, super alloys, copper alloys, aluminum, plastics, ceramics and glass. We understand that you don’t just need testing, you need interpretation. Our engineers and metallurgists consult with you to determine the full scope of every project-factors such as the material of manufacture, the size and shape of the component, and the specification influence the testing decisions. Our metallurgical services include:

- Microstructural Assessment

- Graphite Evaluation

- Inclusion Rating

- Hardness Testing (Rockwell, Brinell & Vickers)

- Reverse Engineering

- First Article Testing

- X-Ray Fluorescent Coating Analysis

For more information on related services, visit our product liability and equipment evaluation pages.

An ATS Family Company

U.S. Forensic is a member of the ATS Family of Companies. With this partnership, our clients have access to most advanced technology housed in a 150,000 square foot engineering laboratory. Failure analysis, metallurgy, materials testing, chemical analysis and a vast evidence storage facility are available to customers.